Additive Manufacturing.

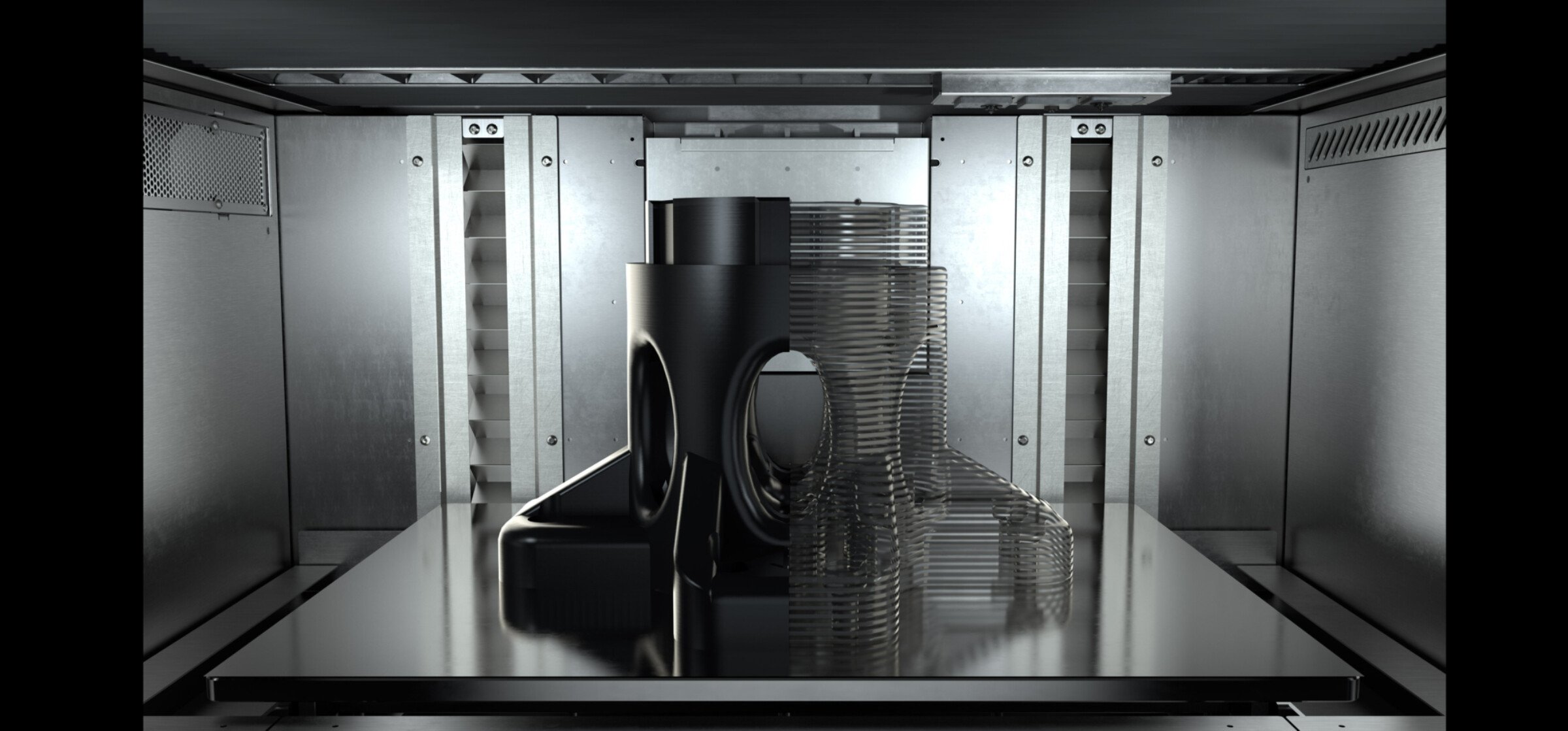

Bringing advanced manufacturing to the heart of Sydney our additive manufacturing division utilises the latest printing technologies to provide prototyping and manufacturing services to a range of sectors within Australia and the APAC region.

About Us.

Fordyno provides a range of additive manufacturing services to support projects ranging from new product development, prototyping through to contract manufacturing.

With our engineering and design tools we have the unique capability to analyse and certify 3D printed components for safety critical applications in transport, aerospace, defence and other industries.

This allows us to create more cost effective, time efficient and locally produced solutions for new projects and replacement parts, including obsolete components.

Our services.

-

At Fordyno, we pride ourselves on our exceptional design and engineering capabilities that enable us to provide unparalleled support to our customers' additive manufacturing requests.

By leveraging the latest advancements in design software and engineering techniques, we can optimize the design of components, reduce production costs, and enhance overall product performance.

Whether it's developing complex prototypes or manufacturing end-use parts, we are committed to delivering high-quality solutions that meet our customers' unique requirements.

-

At Fordyno, we offer a comprehensive range of additive manufacturing (printing) services to cater to diverse customer needs.

Our expertise extends from providing rapid prototyping services for product development, enabling our clients to quickly iterate and refine their designs, to printing obselete or difficult-to-procure parts, ensuring uninterrupted operations and cost-effective solutions.

Additionally, we specialize in contract manufacturing, leveraging our cutting-edge additive manufacturing technologies to produce high-quality components and products at scale.

With our state-of-the-art equipment and meticulous quality control processes, we guarantee the utmost precision and durability in every print.

-

At Fordyno, we understand the critical importance of testing and certifying 3D printed parts for optimal performance and reliability.

With our in-house capabilities, we are equipped to extract essential data such as print path and materials information into our advanced FEA (Finite Element Analysis) software. This enables us to conduct comprehensive analyses that accurately assess the performance of the printed parts.

Furthermore, our physical testing capabilities are enhanced by our state-of-the-art Shimadzu AGX-V2 testing equipment. This allows us to conduct rigorous physical tests on the 3D printed components, ensuring they meet industry standards and perform optimally under various conditions.

Frequently Asked Questions

Understanding how additive manufacturing can support your business is the first step to maximise its value add opportunity. Below we address some our most frequently asked questions.

-

Additive manufacturing (AM) adds value to your business by reducing reliance on the overseas supply chain to reduce the cost of prototyping and production.

Benefits Include:

- Getting products to market quicker

- Reducing manufacturing costs

- Replacing inecient manufacturing workows

- Ability to produce complex or customised products

- Manufacture without tooling or xtures

- Product parts with CAM programming or detail drawings -

No, AM now allows small to medium enterprises (SME) to produce small production runs within the origin country where they were previously incapable. It also minimises costs of large production runs and stock wastage, especially for start-up businesses who may not have the market capacity for large scale production.

Fordyno achieves ,edium volume production via, a setup consisting of multiple smaller Markforged printers. Achieving volume production by printing multiple parts at the same time across different printers.

-

AM is a technology that is inherently sustainable when compared to conventional manufacturing and prototyping processes for product development.

Businesses can now rapidly prototype within minutes of completing their designs, reducing lead time from concept to production, fewer carbon emissions from transport and less waste due to the layer-by-layer build-up process instead of the traditional subtractive method. -

Designers can now rapidly prototype within minutes of completing their designs, reducing lead time from concept to production.

Reducing international or domestic shipping from the existing supplier, not relying on outside companies to complete manufacturing or delivery are all key components to reducing lead time for your team and ultimately your customers.

-

To analyse and truly certify a 3D printed part is a complex task, and our team has extensive experience formulating our own unique methodology to analyse the interaction between multiple materials and properties. This FEA workflow allows us to digitally test thousands of times component performance against relevant standards and certification criteria.

Where calculated values alone cannot give a truley accurate indication of how materials and products will perform in real world scenarios Fordyno provides mechanical testing service via our Shimandzu AGX-V2 Universal testing machine. This provides real world data to ensure that the printed parts meet specifications and comply with the required regulations and quality standards.

-

Fordyno has capabilities to print parts in both metal and thermoplastics including reinforcement fibres.

You can find a full list of materials, material data sheets and design guides here.

Fordyno continues to be at the edge of innovation in additive manufacturing, fostering partnerships to support new material development with our technical and scientific material expertise. -

Additive manufacturing is not limited to specific sectors, however certain applications can really take advantage of the value that AM components offer.

If in doubt contact us and our technical team can advise on your products suitability for industrial additive manufacturing.

-

Our New Product Development division can support our clients with bringing new products, brands and innovations to market.

Our team has been involved in a wide variety of projects across various sectors ranging from large scale mass transportation projects, aerospace components, furniture design right through to product design development for the consumer industries.

Head on over to our NPD division to find our more.